Sprayers, Pulverisers, Turbo Sprayers, Agricultural Machinery.

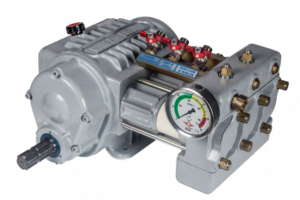

The company Mañez Y Lozano agricultural treatments was formed in 1961 with the project of carrying out phytosanitary treatments on our local farms. Due to the low performance of the sprayers of that time, Mañez Y Lozano designed their own equipment & manufactured the best specific pump on the market.

Through years of work and hands on know-how in this specific line of products, and using their manufacture experience, Mañez y Lozano S.L Agricultural Machinery was formed in 1976.

Our international expectations was kick started in 1989 with the integration of electronic systems in the turbo sprayers, pulverisers & spraying equipment, being the first European company to develop specific systems.

In our facilities we have the latest advances in CNC control numeric machinery performing the complete machining of the various pumps and elements of our machines.